Three Main Causes of Odor in Inks

- Organic pigments and resins

- Plant oils

- Drying processes

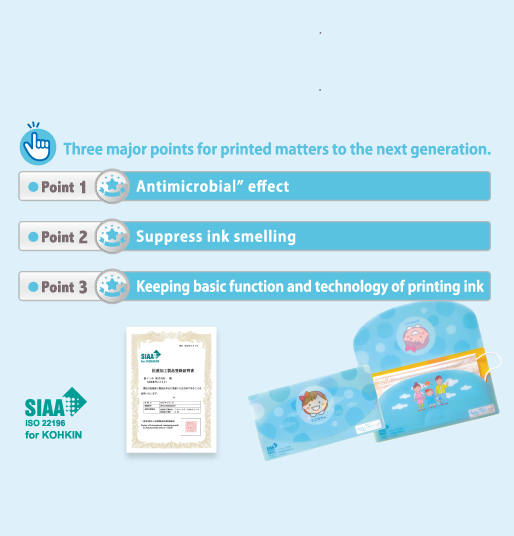

Solutions

- ☑Unpleasant odors are enclosed using a special adsorbent agent (patent pending).

- ☑Antibacterial effect is improved by using a silver-ion compound.

- ☑Compounding expertise is used to ensure that the basic features of the ink are preserved.

Performance and Effects of KUNIO INK

【Key points】

- ・The odor of printed matter is strongest during the drying phase, and can last several hours after printing.

- ・The printed matter is stacked in layers, enclosing the odor.

- ・The accumulation of enclosed odor is unpleasant when the customer uses the printed matter.

- ・KUNIO INK dramatically reduces this accumulation of odor.

Sensory Evaluation of Printed Matter

Evaluation Conditions

- ・Each specimen is tightly sealed in a Tetra Pak bag and sent at room temperature to 10 panelists, who conduct blind sensory evaluations.

- ・The above figure is the average of the evaluation results.

Download

Download the brochure for KUNIO INK here.KUNIO INK SDS

| Product name | Serial number | |

| Ecoheart S Libra NEW KUNIO INK Series | I-30-01 | |